Solutıons

Poultry

Poultry Processing Lines

Poultry Processing Lines provide a complete and fully automated solution for every stage of poultry production, designed to meet the highest international standards of hygiene, safety, and efficiency. From live bird handling and slaughtering to scalding, defeathering, evisceration, chilling, cutting, deboning, and packaging, each process is carefully engineered to ensure smooth operation, high throughput, and consistent product quality.

Built entirely from top-grade, food-safe stainless steel, our poultry processing systems offer superior durability, corrosion resistance, and hygienic performance in demanding production environments. Hygienic design principles allow easy cleaning and fast maintenance, reducing downtime and supporting full compliance with strict food safety and sanitation regulations.

Advanced automation and intelligent control systems minimize manual handling, reduce labor dependency, and optimize process accuracy at every stage. Precise control of processing parameters helps maximize yield, improve portion consistency, and reduce product losses while maintaining high animal welfare and product safety standards.

Our Poultry Processing Lines are suitable for both large-scale industrial plants and mid-sized facilities. Each project is delivered as a fully customized turnkey solution, tailored to production capacity, bird type, processing requirements, and market demands. Whether establishing a new processing plant or upgrading existing operations, AlnixAgro provides scalable systems designed to grow with your business.

With energy-efficient technologies, optimized layouts, and reliable automation, AlnixAgro poultry processing solutions help increase productivity, lower operational costs, and ensure consistent, premium-quality poultry products. From processing to packaging, we enable producers to operate with confidence and compete successfully in global markets.

How It Works

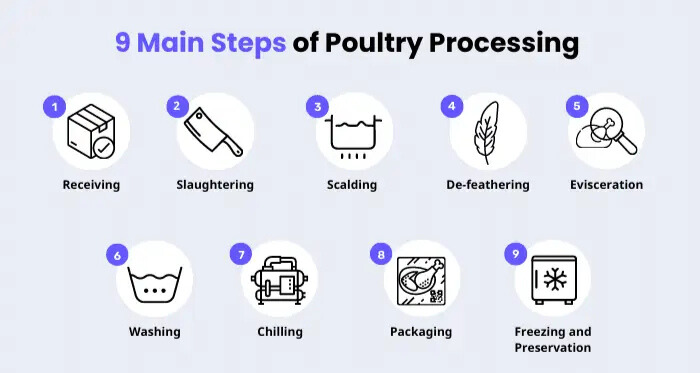

9 Main Steps of Poultry Processing

Receiving: Once the crates of poultry arrive at the processing plant, they are transported to the shackling area via conveyors and then placed in holding cages or modular bins to prevent them from injuring other birds and for proper air circulation.

Slaughtering: In the US, electrical stunning and the use of carbon dioxide are the most common methods to make broilers unconscious or render birds insensible prior to this process. Often, slaughtering is done manually by severing the jugular vein at the ventrolateral base of the bird’s head (sometimes referred to as the modified kosher method).

Scalding: Using hot water set to 53°C, the birds are scalded for 2 to 3 minutes. It’s important to avoid over and under scalding so that the outer layer of skin and feathers are completely and smoothly removed.

De-feathering: Poultry pluckers (or pickers) remove the loose feathers from the scalding process. Also, the carcasses are passed by through flame to remove the filoplumes or hairlike feathers.

Evisceration: Throughout the process, meat inspectors conduct thorough visual inspections to spot bruising, fecal matter, and diseases. While the remaining viscera are discarded, the liver and gizzard are retained; and the latter is also cut, opened, and cleaned. The lungs, kidneys, trachea, esophagus, and crop are all removed manually, while the head is removed using a V-shaped knife or manually as well.

Washing: Poultry carcasses are spray-washed with cold water to remove blood, loose tissues, and other foreign substances from the surface. If these aren’t removed, contamination may occur.

Chilling: Rapid cooling, done in less than 40 minutes, prevents microbial growth. Also, this process is key to enabling the maximum shelf life of the final product.

Packaging: Poultry carcasses are weighed on a pan balance and divided into parts using a knife. The parts are then packed and wrapped, with the legs and giblets in separate trays. After wrapping, inspections are done to verify that the final product is up to par with consumer expectations.

Freezing and preservation: These steps, along with safe food storage , are done to prevent spoilage and deterioration caused by microbes and fat oxidation.

Tips to Avoid Contamination

The risk of contamination is present throughout the various stages of poultry processing. To prevent incidents from occurring at any stage, here are some of the steps that you should take in observing extensive measures and facility cleanliness: